Our Services

All of our services are managed by a team of 3 PCN Level 3 engineers who ensure all of the customer specifications are met in full.

Ultrasonic Inspection

We have the ability to offer ultrasonic inspection both on and off site. Our technicians are a combination of PCN levels 2 and 3. This method of testing is used primarily to detect internal flaws or to characterise materials. We are able to technically review advanced specifications and certify fully in accordance with the most demanding of specifications.

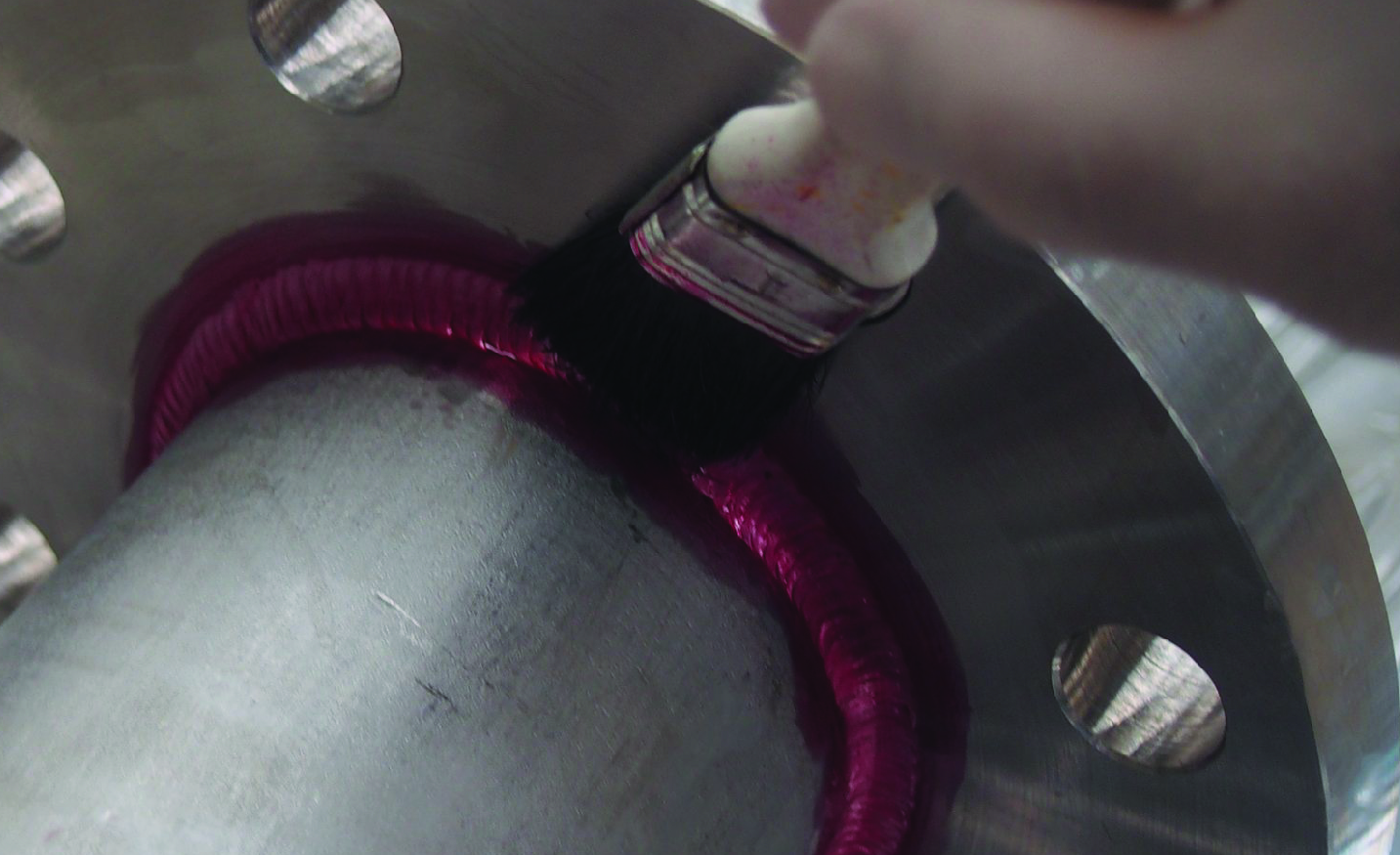

Dye Penetrant Inspection

Our highly qualified PCN Level 2 & 3 technicians use the dye penetrant method of inspection to locate surface breaking defects in non-porous materials. We use various testing methods from fluorescents, colour contrast, water washable, solvent based on the submerged techniques to fulfil this type of inspection.

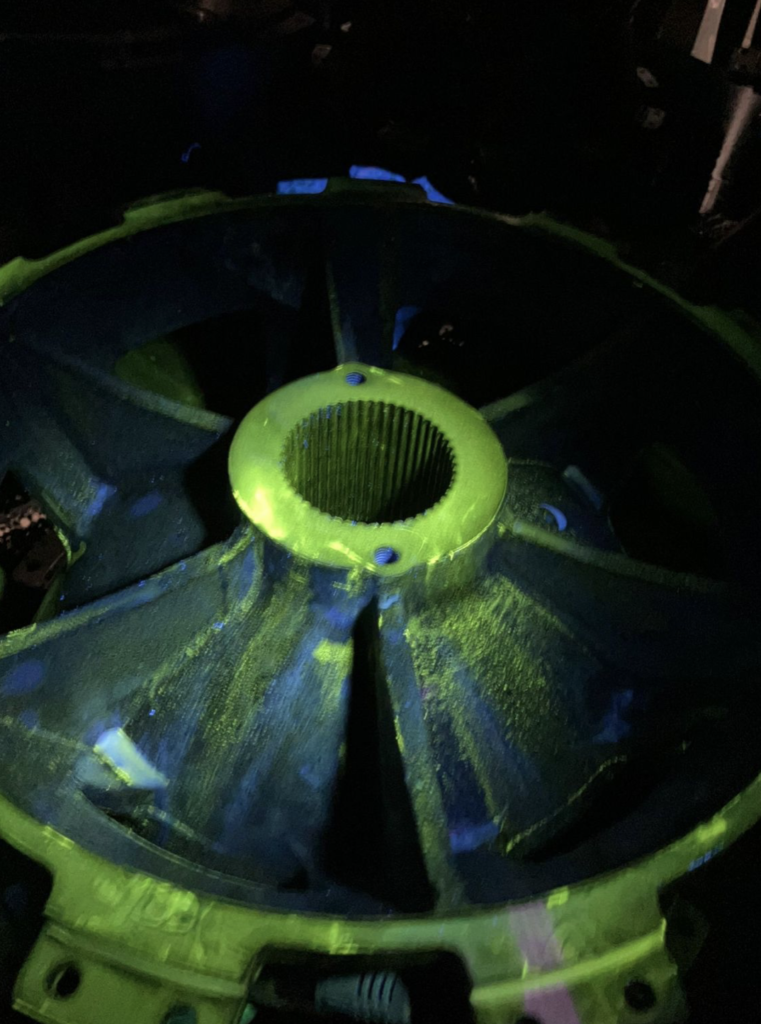

Magnetic Particle Inspection

This method of testing is largely used to detect surface and slightly subsurface discontinuities in ferromagnetic materials. The process involves applying a magnetic field to the part. The piece can then be magnetised by direct or indirect magnetisation. In the instance of flux leakage the particles will build up and form an indication. This will then be further investigated.

On-site Inspections

Our ability to perform on-site inspections, enables us to perform inspections on those hard to reach structures that can not be moved freely. In addition we can also perform on-site inspections to offer lead time advantages to those time critical projects. With technicians available outside of standard working hours we offer the highest standard and flexibility to your business.

Visual Inspection

Available for both on and off site inspection. Visual inspections can check for the quality, type, size, cleanliness and dimensional accuracy of a product. This also includes visual inspection of welds and looks for weld alignment, fit up and joint preparation.

Independent Witnessing

Our inspectors are available at short notice to witness an array of processes and to check for certification compliance and conformity in line with the process being applied.

Radiography

Radiographic metal testing (RT)

Brinell testing

Brinell hardness test

Get in touch?

Got an enquiry?

Fill in our enquiry form to receive our response within 24hrs.